Machine finder

Products

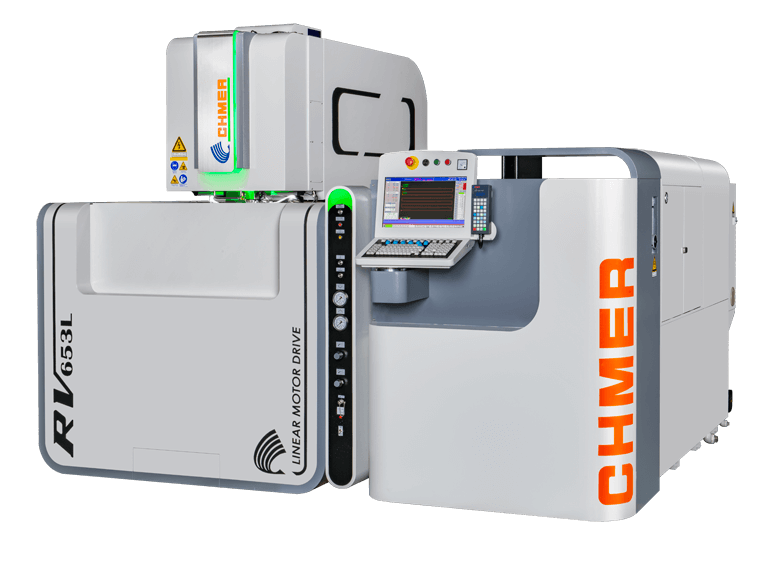

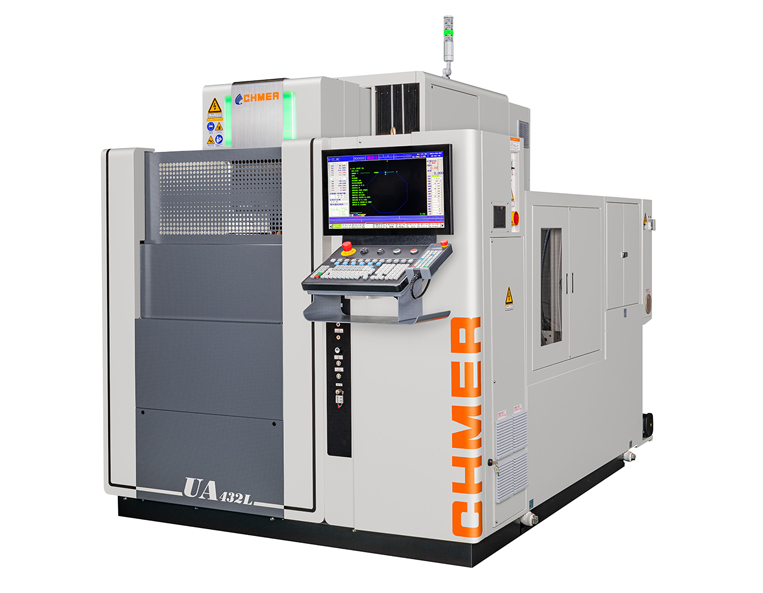

Wire Cut EDM

Wire Cut EDM

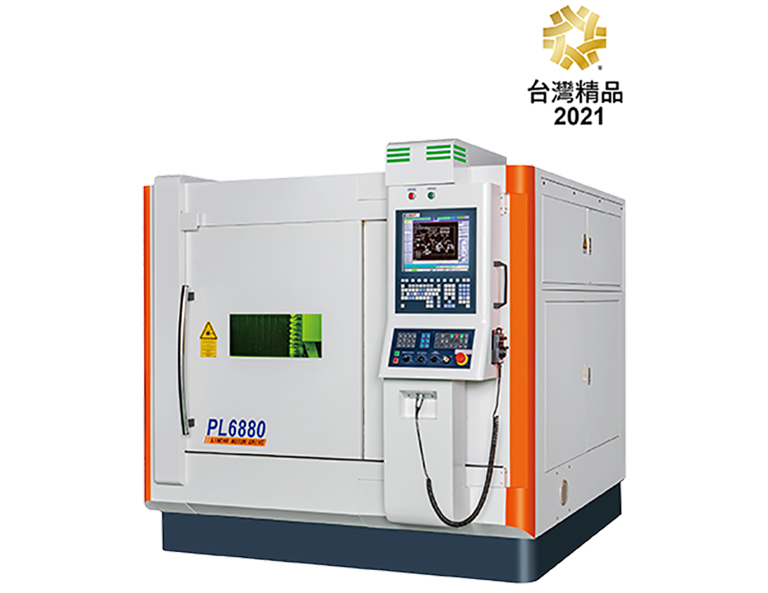

Die Sinker EDM

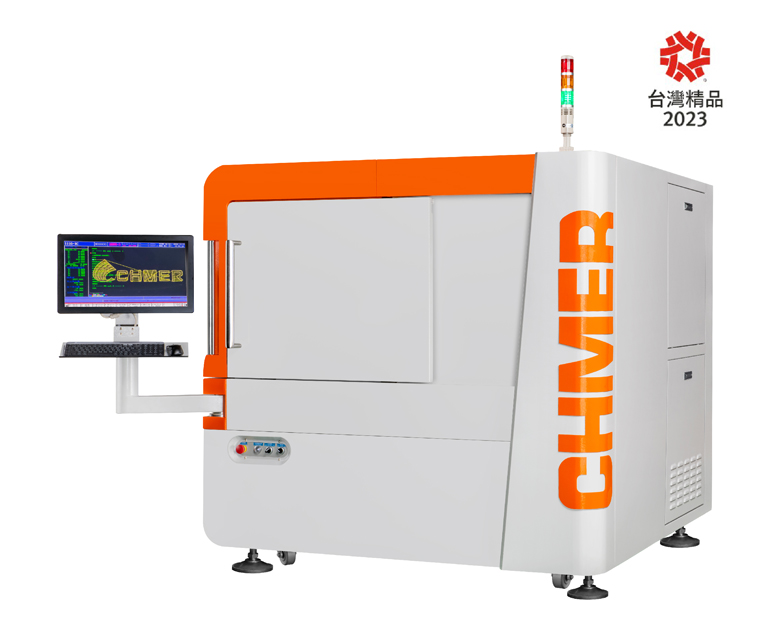

Drilling EDM

High Speed Milling Machine

If you need information about us, please contact us now!!

CHMER is dedicated to advancing the technology and the quality of the EDM industry in Taiwan and worldwide EDM market.