Home::News & MediaPress ReleasesIndustrial and Commercial Times-CHMER smart machinery and equipment demonstrate manufacturing strength

Industrial and Commercial Times-CHMER smart machinery and equipment demonstrate manufacturing strength

2020/07/02

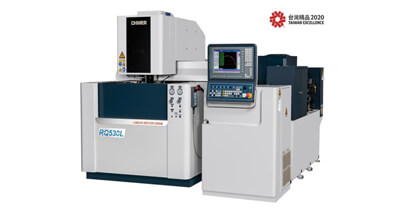

Facing the impact of the pneumonia epidemic on the global economy, CHMER, the number one brand in Taiwan's electrical discharge machine industry, not only participated in the "National Machine Tool Team" to help increase the production of masks and jointly contribute to the fight against the epidemic, but now it has won the 2020 Taiwan Excellence Award. The "RQ530L-Gantry-type wire horse driven wire cutting machine" demonstrates the strong strength of Taiwanese equipment manufacturers in developing smart machinery. With its high-precision and high CP value product performance, it hopes to work together with precision processing companies to create economies. CHMER will participate in the Tainan Automation Machinery and Smart Manufacturing Exhibition from July 2 to 6, booth number: A504.

General Manager Wang Chenhong of CHMER said that the "RQ530L-gantry-type wire horse drive wire cutting machine" that won the 2020 Taiwan Excellence Award masters key technologies. In addition to having a self-made controller, linear motor drive, etc., product innovation focuses on high precision and effective Improve processing efficiency, pay attention to energy conservation and environmental protection, equip with intelligent systems, and demonstrate intelligent machinery integration solutions, including remote connection monitoring, intelligent system services, automated operation integration, etc., with intelligent and high-precision Taiwan quality products as Taiwan's machine tool brands and Industrial upgrading is intensified.

Wang Chenhong pointed out that if there is current demand for precision laser equipment in the industry, most of it needs to rely on imports, because CHMER has a 45-year foundation in developing precision electrical discharge machining and wire cutting machines, and has mastered the key technology research and development and self-made capabilities of high-precision machining, including : Linear motor drive, high-efficiency power supply system, intelligent controller, etc., so the new "PL Series - High-Precision Magnetic Levitation Laser Cutting Machine" and "LC Series - High-efficiency Fiber Laser Cutting Machine" were developed, and these are also used The key technology is installed on professional laser cutting machines, which is of great help to the accuracy requirements and performance required for cutting precision parts. CHMER firmly believes that in times of recession, it must become a strong backing for precision processing customers.

The "High-Precision Maglev Laser Cutting Machine-PL Series" innovatively developed by CHMER is specially used for highly reflective special materials and complex processing. It attaches great importance to the processing needs of precision parts in aerospace, medical, electronics and other industries, and actively meets the needs of aerospace (turbine blade filtration) Internet), medical (high-precision medical equipment), electronics and 3C (fine SMT steel plates, heat sinks, etc.), metal industry (PCD cutting tools)... and other industries' precision parts cutting and processing needs.