Home::News & MediaPress ReleasesEconomic Daily-CHMER won the Taiwan Excellence Award for six consecutive years

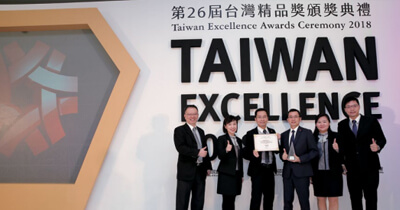

Economic Daily-CHMER won the Taiwan Excellence Award for six consecutive years

2017/12/12

The "AP3020L - Ultra-Precision Three-Axis Linear Motor Engraving Electrical Discharge Machining Machine", which won the Taiwan Excellence Silver Award, has both precision and intelligence. It is a breakthrough in technological innovation and has 7 patents. It is intelligent, high-precision, high-precision, and ultra-low consumption. Product features meet the processing needs of high-precision molds and parts such as high-precision connectors in the 3C industry and IT industry, as well as LED molds.

CHMER General Manager Wang Chenhong said that TYPE C business opportunities have recently attracted attention and the market has grown significantly. TYPE C, IT industry connectors, optoelectronic industry LED and other molds all require high-precision processing. In the past, industrial manufacturing mostly relied on imported high-priced equipment. Based on the determination to serve Taiwan's industry, CHMER actively innovates and develops. After years of experience accumulation and technological breakthroughs, CHMER successfully developed the "AP3020L - ultra-precision three-axis linear motor engraving electric discharge machine" this year, becoming the best for customers with its high CV value. Precision mold equipment partner.

CHMER continues to innovate and develop key technologies. In order to achieve high-precision processing, the AP3020L adopts a new generation of high-rigidity structural design combined with balanced drive to achieve excellent mechanical precision. Paired with a granite platform, it helps reduce capacitance efficiency, reduce consumption and obtain an excellent surface. The three axes are equipped with patented linear motors, which enable high-speed movement, high positioning accuracy and long service life. The processing speed is 35% higher than that of screw machines; consumption is reduced by 27%.

It is worth mentioning that in response to the Industry 4.0 era, in order to help customers carry out smart manufacturing and automated processing operations more effectively, CHMER innovated and developed key technologies. The machine has passed 4 new automation-related patents, including: the automatic hole detection system can Ensure that when processing complex parts, you can stop quickly after drilling to avoid over-processing and damaging the surface. It is also equipped with patented settings such as automatic lifting throttle, automatic processing fluid level control, and automatic Z-axis air pressure balancing device to assist customers in automating operations.