Home::News & MediaPress ReleasesEconomic Daily-CHMER deep hole machine and wire cutting machine for aerospace are eye-catching

Economic Daily-CHMER deep hole machine and wire cutting machine for aerospace are eye-catching

2016/06/16

Taiwan's largest wire cutting machine brand "CHMER CHMER", in conjunction with the 2016 Aerospace Industry and AIM and Productivity 4.0 Industrial Technology Matching Exhibition, exhibited aerospace-specific deep hole machines and high-precision wire horse driven wire cutting machine large-scale machines to actively meet the needs of Mold and parts processing needs of the aerospace industry.

Wang Chenhong, general manager of CHMER, said that the characteristics of the aerospace processing industry include large workpieces, complex shapes, difficult-to-cut materials, composite materials, small quantities and variety, high precision, high quality, etc. Therefore, machine tool manufacturers must focus on the fuselage structure, engine There are corresponding machines to solve various needs such as parts, composite materials or molds.

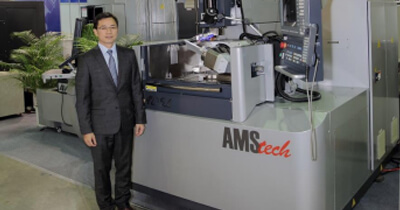

In response to the needs of the global aerospace industry, CHMER developed the "AMS High-Speed Deep Hole Processing Machine-AD Series" specifically for the aerospace industry to meet the needs of the aerospace industry for high-end technical models such as special material processing and special multi-angle processing. It can be applied to the processing needs of turbine blades, combustion chambers, turbine discs, nozzle guide vanes, high-pressure turbine sections, casings, fasteners, etc., and can meet the processing needs of mid-to-high-end parts such as tricky shapes required by aerospace customers. AD series products have made great technological leap forward and compete with international aerospace processing machine tools with extremely high cost performance. Currently, they have been purchased by many aerospace companies at home and abroad.

Under the global Industry 4.0 development trend, CHMER is also actively investing in the Internet of Things and integrating cloud and big data to create smart machinery. Current CHMER machine customers can use the remote monitoring technology developed by CHMER to instantly analyze machine processing status, consumable usage and Availability status, etc., and use the Internet to transmit information to computers and mobile phones to control processing information in real time, greatly improving management convenience.

CHMER is the leader in Taiwan's electrical discharge machining machine industry. Its products include four major product categories: wire cutting machines, electrical discharge machining machines, deep hole machines, and high-speed machining machines. The models developed by CHMER have obvious market differentiation from peers in the industry, and its innovative strength can also Competing with Japanese products at home and abroad, it has adopted the dual-brand strategy of CHMER and AMS in the global market. It hopes to meet the needs of the aerospace market in various regions around the world with a professional and diversified image, and effectively enhance the innovative brand image and brand image of MIT internationally. visibility.