Home::News & MediaPress ReleasesEconomic Daily-CHMER donates equipment to promote productivity 4.0 research and development

Economic Daily-CHMER donates equipment to promote productivity 4.0 research and development

2016/03/16

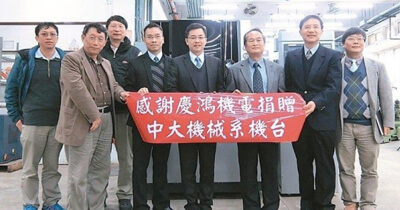

▲ CHMER donated high-precision equipment to National Central University. Tian Yongming, Dean of the School of Engineering (third from right), received the gift on behalf of the machine and presented a certificate of appreciation to CHMER General Manager Wang Chenhong (fourth from right).

"CHMER", the leading brand of Taiwan's electrical discharge machining machine industry, recently donated the "Q4025L high-precision gantry type linear motor wire cutting machine" to the National Central University. In addition to striving to root Taiwan's technical talents and promote industry-university cooperation, CHMER has the latest market trends This model provides teachers and students with course research and field application, further shortening the learning-application gap.

Lai Jingyi, director of the Department of Mechanical Engineering at National Central University, said that CHMER is a benchmark company in the electric discharge machining machine industry. It is also one of the very few Taiwanese manufacturers in the industry that can develop and manufacture the "computer controller" at the heart of machine tools. Moreover, due to the government's vigorous promotion of Productivity 4.0 as an industry As a key strategy for upgrading development, the machines donated by CHMER come at the right time. Because of CHMER’s investment and participation, Central University has more energy in Productivity 4.0 research. It hopes to be closely integrated with industrial development, cross-field integration, and jointly Create greater domestic output value benefits and integrate talent cultivation.

Wang Chenhong, general manager of CHMER, said that in order to expand the industry's connection and contribution to the academic community, CHMER has actively invested in industry-university cooperation. It coincides with the 40th anniversary of the establishment of CHMER, and he is grateful to give back to the society. He is grateful for his time as a student in the Central Mechanical Department and his mentor Yan Binghua. The professor's gift of education and hope to extend this fate infinitely, specially donated this high-precision wire cutting machine.

CHMER's Q4025L high-precision gantry linear motor wire cutting machine has made outstanding achievements. Its product design and R&D innovation capabilities have been recognized by many national awards such as the Taiwan Excellence Award, the Golden Pin Design Award, the National Brand Yushan Award and the National First Prize. It has many An innovation breakthrough in research and development, it adopts the world's first gantry mobile structure design and has won patents from Japan, Taiwan, China and other places. It is currently the most popular mobile phone model on the market.

CHMER actively invests in cultivating talents in the machine tool industry and introduces high-precision equipment to campus. In addition to donating machines to National Central University for Industry 4.0 research, CHMER and Xiangming Technology jointly donated equipment to Mingxin University of Science and Technology, with the hope of reinventing the industry through joint efforts. A better learning environment for technical and vocational students, active investment from the industry, providing academic research energy and technical support, and benefiting students so that they can get a head start before entering the workplace.

Wang Chenhong emphasized that Taiwan’s machine tool production value ranks seventh in the world and its export ranking ranks fourth in the world. Taiwan’s strength cannot be underestimated. He hopes to jointly cultivate outstanding talents and shorten the time by combining long-term investment of resources from academia and business circles. The gap between learning and application is to enhance Taiwan's integration capabilities in technology research and development, intelligent production, etc., and to make Taiwan's machine tool industry more globally competitive.