Home::News & MediaPress ReleasesThe Epoch Times-Millions of machines give back to CUHK to deepen industry 4.0 research on campus

The Epoch Times-Millions of machines give back to CUHK to deepen industry 4.0 research on campus

2016/02/26

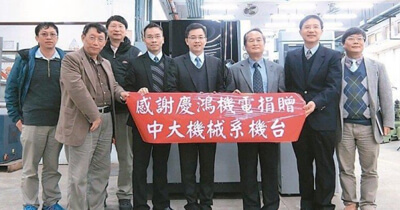

▲ The high-precision gantry-type linear motor wire cutting machine is unveiled for a group photo. From left: Professors Li Zhuyu, Yan Binghua and Huang Yanren from the Department of Mechanical Engineering, Vice President Wang Chenpeng of the Biotechnology Department of CHMER, General Manager Wang Chenhong, Dean Tian Yongming of the School of Engineering, Director Lai Jingyi and Deputy Director He Zhengrong of the Department of Mechanical Engineering.

In order to enhance industry-university cooperation and help students' practical ability to more smoothly integrate with enterprises, CHMER Industrial Co., Ltd., a leading brand in Taiwan's electrical discharge machining machine industry, donated a new high-precision machine with a market value of NT$3.38 million to the Department of Mechanical Engineering of National Central University. Wire cutting machine. The Department of Mechanical Engineering stated that this machine is mainly used in Industry 4.0-related research and will be of great help to teachers’ teaching research and students’ practical operations.

Wang Chenhong, general manager of CHMER, said that CHMER has long been actively involved in industry-university cooperation. As an alumnus of the Institute of Mechanical Engineering of CUHK, he is grateful for the teachings of the Department of Mechanical Engineering of his alma mater and his mentor Professor Yan Binghua. He hopes to extend this fate infinitely and specially donates high-precision wire cutting machines. machine.

He said that this "high-precision gantry-type linear motor wire cutting machine" adheres to the four major design concepts of innovation, technology, green energy, and efficiency. Its product design and R&D innovation capabilities have won the Taiwan Excellence Award, the Golden Pin Design Award, and the National Brand He has been recognized by many national awards including the first prize of the Yushan Award, as well as patents in Japan, Taiwan, China and other places.

The machine is equipped with a self-developed linear motor, which greatly improves the processing accuracy; the streamlined design greatly reduces costs and maintenance; the first energy-saving circuit saves more than 20% of electricity, and adopts a high-precision temperature control system. Many energy-saving designs lead Taiwan's EDM industry Green energy technology development; the machine uses self-developed and manufactured controllers, with full ownership of software and hardware. CHMER introduces this high-precision equipment to the campus, hoping that the investment from the industry will provide academic research energy and technical support, and benefit students, so that students will have a good starting point before entering the workplace.

The Department of Mechanical Engineering stated that as the largest department of Central University, the department has trained countless talents since its establishment nearly 40 years ago and has been highly recognized by the industry. Currently, the government is vigorously promoting Productivity 4.0. As a key strategy for industrial upgrading and development, the machines donated by CHMER come at the right time!