Home::News & MediaPress ReleasesIndustrial and Commercial Times-CHMER Aerospace Deep Hole Machine Large Factory Procurement

Industrial and Commercial Times-CHMER Aerospace Deep Hole Machine Large Factory Procurement

2015/09/03

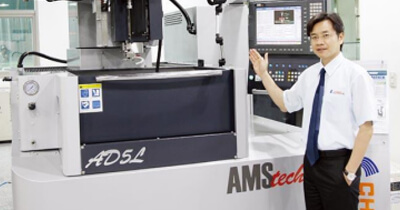

▲ The AMS high-speed deep hole processing machine-AD series developed by CHMER specifically for the aerospace industry actively meets the needs of aerospace customers for processing medium-to-high-end precision parts made of special materials and tricky appearances, and has won high praise and favor from domestic and foreign aerospace buyers.

The only domestic exhibition of military and civilian aerospace products and defense weapons and equipment, the Taipei International Aerospace and Defense Industry Exhibition, has been on display for four days with fruitful results. The number of exhibitors and foreign buyers has reached a new high, and the number of visitors has increased by nearly 10% compared to the previous event. Five percent. CHMER exhibited the AD series of high-speed deep hole machines specifically for aerospace at the exhibition, providing professional machine equipment required for mid-to-high-end parts processing by the aerospace industry. It showcased high-precision processing technology and applications, and was well received by domestic and foreign aerospace buyers. favor.

Wang Chenhong, general manager of CHMER, said that in response to the special materials and complex curved surface processing requirements of the aerospace industry, the "AD" series of deep-hole electric discharge machining machines specifically developed for aerospace industry can be used to process special aerospace alloys quickly but at low cost. The processing characteristics of electrode consumption; the self-made 6-axis deep hole dedicated controller with the self-made rotary/tilt index plate can achieve 6-axis control. If equipped with automatic electrode and eye mold exchange, it can reach 8-axis control, breaking through the traditional deep hole machine. For hole processing, the AD series has been improved to perform processing on curved surfaces with complex shapes; equipped with automatic depth measurement function, blind hole processing can be performed; and the controller can perform automatic tool compensation to ensure that the required depth can be accurately achieved; The processing mode adds the discharge engraving and milling mode of high-end discharge technology, which can be applied to turbine blades, combustion chambers, turbine disks, nozzle guide vanes, high-pressure turbine sections, casings, fasteners, etc., to meet the tricky appearance required by aerospace customers. and other mid-to-high-end parts processing needs.

General Manager Wang Chenhong of CHMER further said: Domestic and foreign aerospace manufacturers are actively seeking breakthroughs in key component manufacturing technologies in order to gain global competitiveness, and professional equipment manufacturers can serve as the best support for the needs of aerospace production. CHMER has also actively invested resources in customized aircraft models, hoping to grow and create success together with its aerospace customers. In response to the needs of the global aerospace industry, this exhibition displays the "AMS high-speed deep hole processing machine-AD series" specially developed for the aerospace industry. It is to achieve the aerospace industry's high-tech requirements for special material processing and special multi-angle processing. A model developed to meet grade requirements. AD series products have made great technological leap forward and compete with international aerospace processing machine tools with extremely high cost performance. Currently, they have been purchased by many aerospace companies at home and abroad.

CHMER Group actively promotes its own brands to effectively enhance the brand image and visibility of MIT. It also adopts the dual-brand strategy of CHMER and AMS in the global market, hoping to meet the market needs of various regions with a professional and diversified image. CHMER's innovative strength cannot be underestimated and has won numerous national awards in recent years. Including the "National Industrial Innovation Award", "Outstanding Backbone Enterprise Award", "Industrial Elite Award" sponsored by the Ministry of Economic Affairs, "Taiwan Quality Award" representing Taiwan's product innovation value image, "Golden Pin Design Award", "National Brand Yushan" Award" and so on.