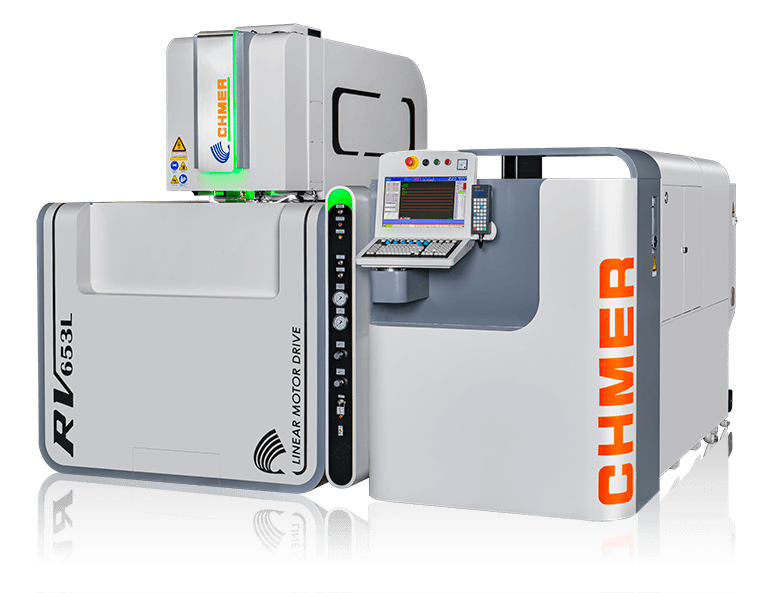

RV653L

Wire Cut EDM

Brand new design for the cutting edge of intelligent system and professional machining technologies includes real-time processing monitor, M to M networks, production management and new intelligent machining system.

Specification

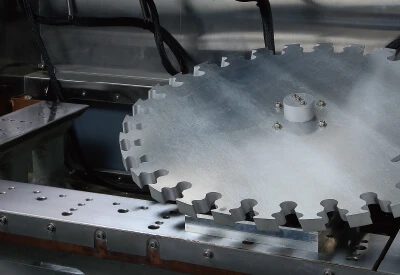

Extraordinary Performance

Tailored designs for the molds and spare parts of aerospace, automobile, energy and electronics.Excellent indexing accuracy and convenience by working with the self-developed highly accurate submerged rotary table.

High Rigid Structure Column

The best and rigid design by FEA (Finite Element Analusis). Three large span linear guideways with a fixed table for heaby loads. Ensuring hith accuracy as a small sized machine.

Revolutionary i8 Poser Supply

Faster cutting speed (increasing 15% on 150mm workpiece and saving energy by 20%). More powerful wire bread suppression, which increases the machining stability and decreases the accuracy error.

Improved heat dissipation and cooling system with the thermal reduced i8 components, maintains the machine temperature in continued and high-speed machining for longer PCE use without the trouble of malfunctions.

Intelligent Regulated Power Supply

New developed IVC, high frequency switching power supply for regulating and adjusting the voltage. Ensuring the machining temperature and safety by separating the load and the power.

Using the advanced technology to efficiently regulate the unstable external power to high precise internal power and intelligently determine more energy on high energy cutting for higher accuracy.

Portability & Intelligence

Providing all information using mobile devices, during your absence from the machine. Experience the new intelligent machinery ear of full portability management.

The Intelligent Information Center

The Kanban information for having instant machine data through servers and building the machining history.

APP Monitoring System

The exclusive Android APP for mobile phone and tablet, for multiple instant information including machine status, utility, spare parts life management and machining path monitor... etc.

Active Communication Software Service

Having instant data through software such as LINE & E-MAIL.

Website Service

After accessing the system, all information is shown directly including machine status, utility, spare parts life management and machining path monitor… etc.

If you need information about us, please contact us now!!

CHMER is dedicated to advancing the technology and the quality of the EDM industry in Taiwan and worldwide EDM market.