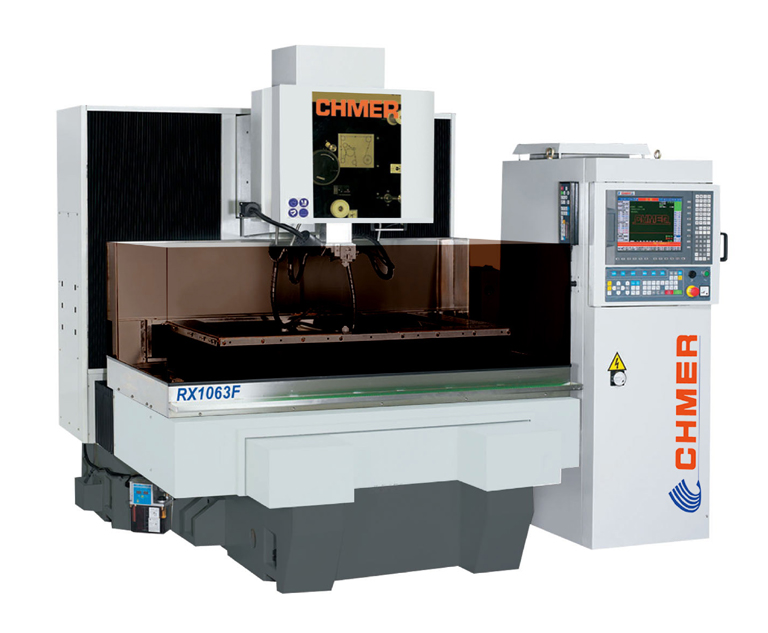

RX1063F

Wire Cut EDM

1.Economical processing costs combined with highly flexible operation.

2.Suitable for wire cutting processing applications of large-sized molds and machined parts.

3.Large-scale home appliances, automotive industry and other large-scale mold processing preferred.

X, Y, Z Axis Travel

U, V Axis Travel

Max. Size of Workpiece

Max. Work Piece Weight

Outside Dimension (WxDxH)

Machine Weight

1000x600x300mm

150x150mm

1430x900x295mm

3000kg

2700x3000x2200mm

6500kg

Specification

Standard

- Paper Filter x 4PCS

- Diamond Guides x 2PCS

- Upper/Lower Flushing Nozzles x 2PCS

- Energizing Carbides x 2PCS

- Diamond Guide Remove Jig

- Brass Wire (DIA.0.25mmX5kg)

- Tools

- AC Power

- Alignment Jig

- Flushing Ion Exchange Resins(1PCS x 3L)

- Submerged Ion Exchange Resins(1PCS x 6L)

- Swinging Panel

- Auto Data Recovery after Blackout

- Water Chiller (Flushing) x 2T

- Water Chiller (Submerged) x 2T

Option

- 2-in-1 Transformer + AVR

- Auto Wire Threading(AWT)

- 30kgs Wire Feeder

- Auto Wire Chopper(30kg)

- DC Invert Chiller x 2T

If you need information about us, please contact us now!!

CHMER is dedicated to advancing the technology and the quality of the EDM industry in Taiwan and worldwide EDM market.